Stainless Steel Welding Techniques: Differences and Application Areas Between TIG vs. MIG

Stainless steel is an indispensable material in many industries due to its durability and aesthetics. However, in order to successfully weld this material, it is very important to choose the right welding technique. In today's article, we will discuss the two most preferred welding methods. TIG (Tungsten Inert Gas) And MIG (Metal Inert Gas) We will compare welding techniques, detailing their differences and areas of application. This practical guide will help you choose the most suitable method for your welding projects!

What is TIG Welding?

TIG welding, is a welding method using tungsten electrodes and protected with inert gas (mostly argon or helium). Especially preferred in welding processes of sensitive materials such as stainless steel, TIG allows you to obtain superior quality and clean weld seams.

Advantages of TIG Welding

- High Quality: Thin, smooth and aesthetic weld seams are obtained.

- Temperature Control: Thanks to precise control of heat input, the risk of deformation of the material is reduced.

- Clean Process: Low scrap and minimal weld seam defects, resulting in a cleaner result.

- Sensitive Applications: It shows superior performance in processes requiring fine materials and details.

Disadvantages of TIG Welding

- Slower Processing: The production speed is not as high as MIG welding.

- High Operator Skill: It is a technique that requires expertise and experience.

- Equipment Costs: The TIG machine and electrodes may be more costly than MIG.

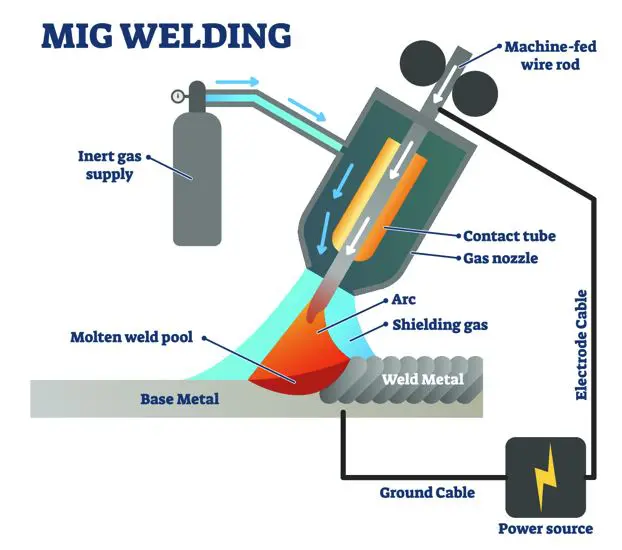

What is MIG Welding?

MIG welding, is a welding method performed using continuously melting filler wire and inert gas (mostly argon or argon mixtures). MIG welding, which is frequently preferred in automation and mass production, stands out with its high production speed and economical costs.

Advantages of MIG Welding

- Rapid Production: It is ideal for mass production thanks to its high welding speed.

- Ease of Use: It minimizes operator errors by working integrated with automation systems.

- Lower Cost: It is an economical solution in terms of equipment and wire consumption costs.

- Productivity: Provides high efficiency in large-scale production.

Disadvantages of MIG Welding

- Less Sensitivity: It can be difficult to achieve weld seams as thin and aesthetic as TIG.

- Heat Dissipation: Since heat control is not as precise as TIG, the risk of material deformation may increase.

- Additional Cleaning Requirement: Further post-weld cleaning operations may be required.

Main Differences Between TIG and MIG

| Feature | TIG Welding | MIG Welding |

|---|---|---|

| Processing Speed | Slower, requires precise control | Fast, suitable for mass production |

| Quality | High-end, aesthetic and clean seams | Sufficient quality, but aesthetic results may vary |

| Heat Control | Very precise, minimal risk of deformation | Medium level, heat dissipation could be wider |

| Operator Requirement | High skill and experience required | Less expertise required, automation advantage |

| Cost | Higher equipment and gas consumption | Economical, low-cost equipment |

Application Areas

Areas of Use of TIG Welding

- Delicate Fine Works: Aesthetic and clean seams in materials such as stainless steel and aluminum.

- Aerospace and Automotive: Production of parts where high performance and appearance are critical.

- Decorative and Artistic Applications: Designs and special projects requiring fine details.

Areas of Use of MIG Welding

- High Production: Mass production lines and automatic welding systems.

- Industrial Assembly: Pipelines, frame production and large-scale metal structures.

- General Production: It is preferred in projects where speed and cost effectiveness are sought.

Practical Tips and Suggestions

- Material Preparation: In both welding methods, it is very important that the stainless steel to be welded has a clean and smooth surface.

- Correct Gas Mixture: Correct adjustment of the shielding gas (argon/helium) used directly affects the welding quality.

- Equipment Selection: Be careful to choose the welding machine, electrode and filler wire that suits your project's requirements.

- Operator Training: Preferring experienced and trained operators in welding processes minimizes errors.

- Trial Resources: Determine the most appropriate settings by making trial welds before starting production.

Frequently Asked Questions (FAQ)

Question: What is the most important factor when choosing between TIG and MIG welding methods?

Reply: The choice depends on factors such as the requirements of your project, the type of material, the quality of the weld and the production speed. TIG can be preferred for precise and aesthetic welds, while MIG can be preferred for high production speed and economical solutions.

Question: What are the most common problems in stainless steel welding?

Reply: Heat control, material deformation and weld seam defects are the most common problems. To prevent these problems, the use of correct equipment and experienced operators are of great importance.

Question: What advantage does automation provide in MIG welding processes?

Reply: Automation reduces operator errors, increases welding speed and ensures consistent weld quality – an important advantage, especially in mass production.

Conclusion

When welding stainless steel, choosing between TIG and MIG welding techniques depends on the specifics of your project. TIG welding, is an ideal choice for sensitive and aesthetic welds, MIG welding It offers high production speed and economical solutions. Both methods have their own advantages and application areas; choosing the right method is critical in terms of occupational safety, efficiency and quality.

By reviewing this guide, you can determine which method is more suitable for your stainless steel welding processes and increase the success of your project. Don't forget to follow our blog for more welding tips and technical information!

Stay tuned for more content and practical tips on advanced welding techniques!

Why Should You Choose Samas?

- Quality and Durability: Our stainless steel products are precision-crafted for unmatched quality and long-lasting durability.

- Eco-Friendly: Prioritizing sustainability, our stainless steel is fully recyclable and has a low environmental impact.

- Exceptional Service: Our dedicated team ensures a hassle-free shopping experience with prompt assistance for all your questions.

- Affordable Luxury: Access premium stainless steel products at competitive prices without compromising quality.

- Trusted Reputation: Through years of experience, we have built a reputation for excellence and reliability.

- Satisfaction Guaranteed: Your happiness is our priority. If you are not satisfied, we promise to do whatever is necessary for your satisfaction.

Experience the excellence of Samas Stainless Steel today. We look forward to welcoming you to our offices around the world!

Comments are closed