From Earth to Space: How Stainless Steel Revolutionized Spacecraft Design.

The conquest of space has been one of humanity's most daring undertakings. This is a testament to our ingenuity and marks the dawn of a new era in which the stars are accessible. But the vision of space exploration, romantic as it was, required more than rocket fuel and dreams; A material was needed that could withstand the countless rigors of space and ultimately bring our explorers home. Stainless steel has become the shining hero, adapting to the harshest conditions to support and truly shape the future of space travel.

Evolution of Spacecraft Materials

Before stainless steel, available materials for spacecraft design were limited and often specialized based on their purpose. Aluminum alloys were the dominant choice due to their light weight and machinability, while titanium began to gain ground due to its strength-to-weight ratio. However, space exploration required more corrosion-resistant and durable materials.

Development of Stainless Steel

The introduction of stainless steel in the mid-20th century was an important turning point. Its unique combination of properties, including high strength-to-weight ratio, corrosion resistance, and thermal properties, made it an ideal candidate for use in spacecraft.

Advantages of Stainless Steel in Spacecraft Design

Stainless steel's revolutionary role in spacecraft design can be attributed to its numerous benefits that directly address the environmental challenges of the final frontier.

High Strength-to-Weight Ratio

The strength of stainless steel is well documented for its applications in the aerospace industry, particularly in rocket propulsion and spacecraft structure. This strength is essential to withstand the intense forces of launch and the unyielding vacuum of space.

Corrosion Resistance

Space is a harsh and unforgiving environment where materials can deteriorate over time. Stainless steel's resistance to corrosion is crucial to the longevity and safety of spacecraft.

Thermal Properties

The extreme temperatures experienced during a space mission require a material with excellent thermal properties. The ability of stainless steel to withstand both freezing cold and scorching heat without losing its integrity is an important reason why it is still used in spacecraft construction today.

Durability in Tough Conditions

From micrometeorites to re-entry stress, spacecraft materials must withstand a range of adversities. Stainless steel provides the flexibility needed to overcome these challenges without fail.

Spacecraft Design and Impact on Missions

The versatility of stainless steel has ushered in a new era of spacecraft architecture and enabled engineers to redefine what is possible in space exploration.

Case Studies on Stainless Steel Applications

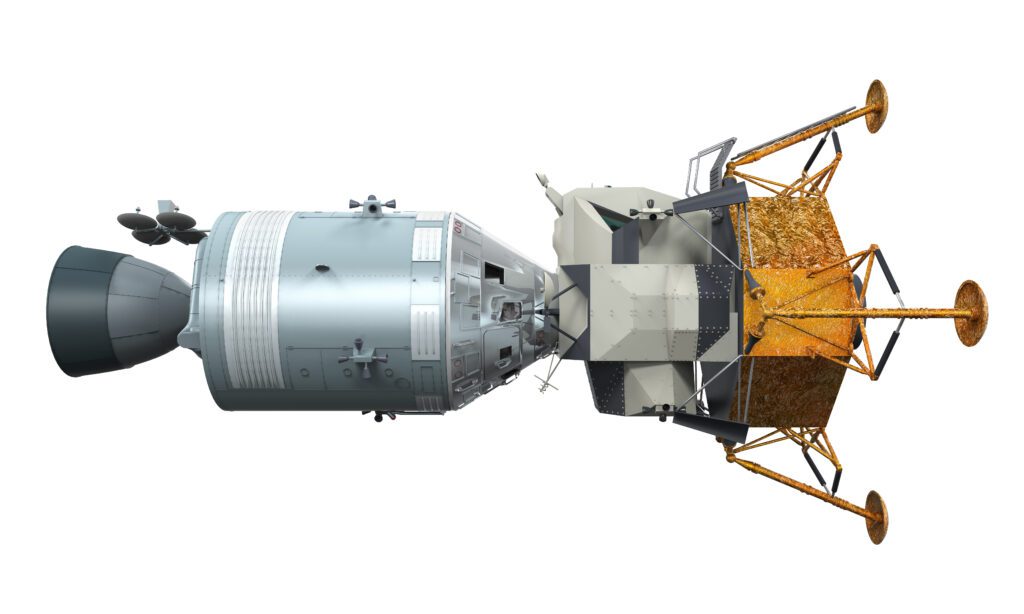

SpaceX's Starship, designed for interplanetary travel, exemplifies the modern application of stainless steel for its heat shield and structure. This new approach has helped overcome the previous limitations of non-reusable and heat-sensitive materials. The historic Apollo Lunar Module, which took astronauts to and from the Moon, also featured extensive use of stainless steel, demonstrating its reliable role in key spacecraft components.

Improved Abilities and Performance

The introduction of stainless steel has led to spacecraft designs that are not only durable but also lighter, allowing for greater payload capacity. As a result, the application of stainless steel has directly contributed to more ambitious space missions and made spacecraft reusability a practical reality.

Challenges and Innovations

Despite its numerous advantages, stainless steel's journey into space was fraught with difficulties. Technical obstacles and material limitations required innovative solutions to fully exploit its potential.

Overcoming Technical Obstacles

A key challenge with stainless steel is managing its weight, as even a small reduction in weight can significantly impact fuel efficiency. Engineers are constantly fine-tuning design and manufacturing processes to produce lighter yet still durable components.

Innovations in Production

Advances in stainless steel production, including new alloy compositions and fabrication methods, have further expanded its applications in space technologies. These innovations have also reduced the costs associated with space exploration and supported the burgeoning commercial space sector.

Future Applications and Possibilities

There are chapters of the story of stainless steel in space that have yet to be written. As we set our sights on further space exploration, the role of this material in shaping the next generation of spacecraft is poised to increase.

Potential Developments in Stainless Steel Technology

Research into new alloys and composite materials could push the boundaries of what stainless steel can achieve in interplanetary environments. These advances have the potential to unlock even more sophisticated and flexible spacecraft designs.

Implications for Future Space Missions

The continued development of stainless steel-based space technology holds promise for future missions, including potential human settlements on other celestial bodies. Its use could not only make these tasks possible, but also contribute to their long-term sustainability.

Conclusion

From Sputnik to the modern space age, stainless steel's journey with astronauts and cosmonauts has been an integral part of humanity's exploration of the cosmos. As we stand on the threshold of new interplanetary horizons, the continued evolution of stainless steel represents not just a chapter in the book of space travel, but a continuing testament to our collective ability to innovate and adapt.

The legacy of this material is reliability, durability and the promise of a future where the stars are no longer out of reach. It stands as a metaphor for the indomitable spirit of discovery and a beacon that guides us to new scientific discoveries and the expansion of our horizons – literally from Earth to space.

Why Should You Choose Samas?

- Quality and Durability: Our stainless steel products are precision-crafted for unmatched quality and long-lasting durability.

- Eco-Friendly: Prioritizing sustainability, our stainless steel is fully recyclable and has a low environmental impact.

- Versatile Style: Find modern kitchen appliances, stylish decor and more to beautify any space with timeless stainless steel designs.

- Easy Maintenance: Enjoy trouble-free cleaning and resistance to corrosion with our easy-to-maintain stainless steel products.

- Exceptional Service: Our dedicated team ensures a hassle-free shopping experience with prompt assistance for all your questions.

- Affordable Luxury: Access premium stainless steel products at competitive prices without compromising quality.

- Trusted Reputation: Through years of experience, we have built a reputation for excellence and reliability.

- Satisfaction Guaranteed: Your happiness is our priority. If you are not satisfied, we will fix it.

Experience the excellence of Samas Stainless Steel today.

Comments are closed