Innovation in Wearable Technology: Fusion of UHMWPE Fabric and Flexible Electronics

The convergence of textile engineering and electronics has opened a new horizon in the wearable technology sector. At the forefront of this breakthrough is Ultra High Molecular Weight Polyethylene (UHMWPE) fabric, a material once renowned for its exceptional strength-to-weight ratio in industrial applications. But the story of UHMWPE witnesses a transformative chapter with its emergence as a fundamental textile in the field of flexible electronics. This isn't just materials science; a movement that is shaping how we interact with technology on a deeply personal level.

In this comprehensive review, we will explore the profound impact UHMWPE fabric can have on the integration and functionality of wearable devices and flexible sensors. Our research is not just theoretical; We dive deep into real-world examples, pioneering studies, and case studies that illuminate how far the fusion of UHMWPE fabric and electronics can take us.

UHMWPE Fabric in Wearable Electronics

UHMWPE: A Material of Possibility

The emergence of UHMWPE fabric in wearable electronics is not a random event; It is a strategic shift towards materials that can accommodate the dynamism of human movement. UHMWPE meets this challenge with gusto. It exhibits superior mechanical properties, is extremely lightweight, and has numerous other features that make it an ideal competitor in the wearable technology arena. Integrated with conductive elements, UHMWPE fabric becomes a conduit between the human body and the electronic spectrum.

Weaving UHMWPE into Smart Clothing

This fabric is now the canvas for a new kind of art: smart clothing. Think fitness trackers, motion-sensing clothing, and even mood-reflecting clothing. UHMWPE fabric forms the backbone of these innovations, providing the structure and comfort needed for something as personal as clothing while seamlessly housing the electronic components that give these textiles their “smart” moniker.

Advances in Flexible Sensors

The Role of UHMWPE in Enhanced Sensory Experience

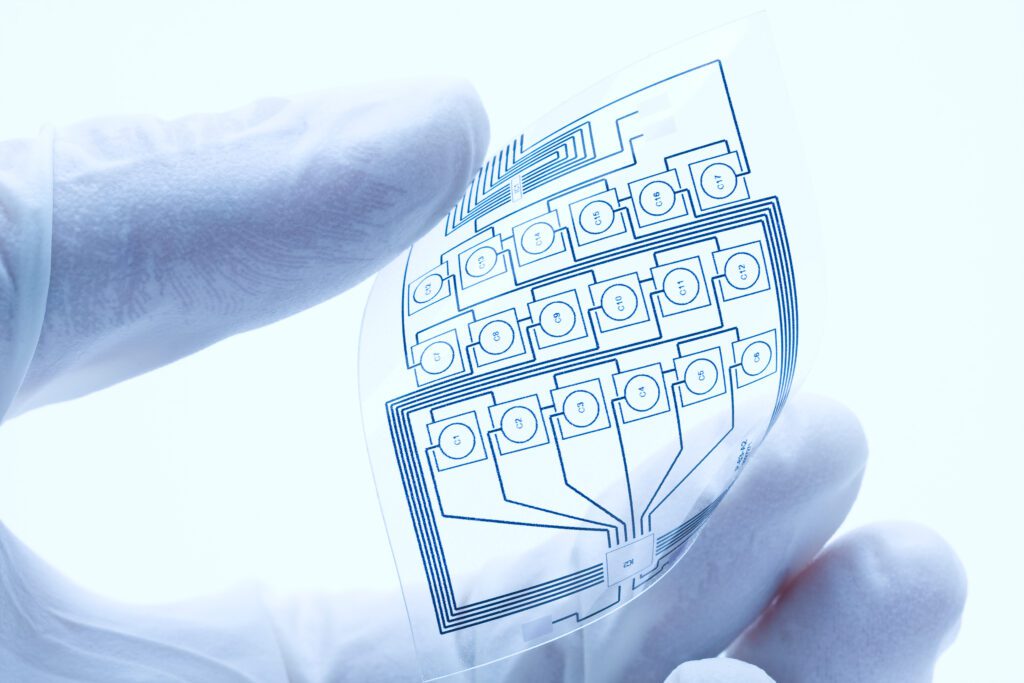

Sensors, more than any other component, define the utility of wearable electronics. When UHMWPE is designed specifically for sensors, it gives them an unprecedented degree of flexibility. This flexibility is crucial to ensuring that sensors can maintain their physical integrity while adapting to the wear and tear of human activity. Moreover, the ultra-thin structure of UHMWPE-based sensors allows them to integrate seamlessly into the fabric, providing a sensory experience that is virtually indistinguishable from regular clothing.

Applications Covering Sectors

The versatility of UHMWPE fabric is not limited to just one industry. Sensor integration has wide-ranging applications, from healthcare with bandages that monitor wounds in real time, to sports where biometric feedback is crucial to pushing the limits of performance, to industrial safety where smart workwear can detect environmental hazards.

Challenges and Solutions

Maintaining Durability and Flexibility

As perfect as the marriage between UHMWPE and electronics sounds, it is not without its hiccups. One of these hurdles is ensuring the durability of these integrated systems. Wearables are, by their nature, meant to withstand the rigors of daily use. Textiles have historically outlived the precision lifespan of electronics. Combining both poses an engineering challenge balancing the durability of UHMWPE with the complexity of electronic components.

Strategies to Overcome Integration Challenges

Fortunately, innovators are working hard to develop solutions. From advanced bonding techniques that secure electronics to UHMWPE to pioneering sensor designs that more effectively dissipate stress, the industry is fostering an environment where functional, wearable devices can thrive.

Future Expectations and Innovations

Emerging Trends and Developments

The exciting innovation around UHMWPE is not just a flash in the pan; It marks a fundamental shift in the trajectory of wearable technology. Emerging trends highlight UHMWPE's role not only in the flexibility of electronics, but also in promoting sustainability as a material that promises biodegradability without compromising performance.

Implications for the Wearable Technology Industry

The rise of UHMWPE has tremendous implications for the wearable technology industry. It is democratizing technology in a way never seen before: integrating electronic intelligence into the fabric of our lives. At this rate, UHMWPE fabric not only shapes clothes; It shapes an entire industry.

Case Studies Showing the Potential of UHMWPE

Conductive UHMWPE Fabric Increases Thermal Resistance

Recent studies have opened a new era in UHMWPE fabric applications. One of these breakthroughs is the creation of conductive UHMWPE fabric with improved thermal resistance. Shielding electromagnetic waves and actively maintaining the temperature of wearable devices, this fabric is a testament to the versatility that UHMWPE brings to the table.

Ballistic Resistance Studies Highlight the Armor Potential of Fabric

A study on the ballistic resistance of UHMWPE textiles underlines the material's pioneering potential in protective clothing. Ballistic resistance dominated by yarn tensile strength puts UHMWPE in line with modern armor yarns, opening doors for advanced personal protection equipment.

MIT's Smart Textiles: A Milestone for Wearable Technology

In an academia-industry convergence, MIT has created a smart textile that not only adheres to the body but also detects posture and movement. This outlines the role of UHMWPE as a tool for enhanced user experience, offering insights beyond the obvious through real-time sensory feedback.

Final Thoughts

The journey of UHMWPE fabric from the years of industrial engineering to the forefront of wearable technology is much more than a scientific narrative; It is a social narrative. It's about expanding the boundaries of what we can achieve, both in terms of personal technology and our relationship with it. As we embrace the fabric of innovation that UHMWPE offers, we are setting new standards for what it means to be connected, not just digitally but as an extension of the devices we create.

Why Samas?

- Unmatched Durability: Our UHMWPE textiles offer superior strength and abrasion resistance for a variety of applications.

- Lightweight and Flexible: Despite their strength, our textiles are lightweight and flexible, perfect for versatile applications.

- Superior Performance: Rely on our textiles for ballistic protection, cut-resistant hardware and high-strength applications.

- Eco-Friendly: Our textiles produced from sustainable materials minimize environmental impact.

- Special Solutions: Get custom solutions to meet your unique project needs.

- Competitive pricing: Enjoy the highest quality textile products at affordable prices.

- Special Support: Our customer support team is here to help you every step of the way.

Choose Samas for high-performance UHMWPE textiles that meet your needs and exceed your expectations.

Comments are closed