Revealing the Durability of Stainless Steel Ropes in Gravity-free Environments

Beyond the clouds, in the silent vastness of space, lies an arena where materials face challenges unimaginable on Earth. For aerospace engineers and space technology enthusiasts, the durability of materials such as stainless steel wire ropes is of great importance. This article explores the extraordinary strength and versatility of stainless steel wire ropes by examining their behavior and applications in the zero-gravity framework, an environment that tests the limits of human technology.

Understanding Stainless Steel Ropes

Stainless steel wire ropes represent the pinnacle of materials engineering, consisting of individual steel strands twisted or braided to form a flexible yet sturdy cord that can withstand tremendous forces. Their high tensile strength, corrosion resistance and ability to withstand extreme temperatures make them indispensable in various industries and are particularly relevant in aerospace due to the stringent demands of space.

Composition and Properties Explained

Essentially a composition of stainless steel alloys, these ropes inherit the tough properties of their components, which typically include elements such as chromium, nickel and manganese. The synergy of these materials results in exceptional mechanical properties that enable stainless steel wire ropes to maintain their structural integrity under stress.

A Lifeline in Aviation and Space

Stainless steel wire ropes play a supporting role in a multitude of aerospace applications, from lifting and elevating in construction to the placement and manipulation of equipment both inside and outside an orbital stage, underlining their versatility and strategic importance in space exploration.

Challenges Encountered in Zero Gravity Environments

The vacuum of space presents two different conditions: the absolute cold in the shadows of celestial bodies and the searing heat of unfiltered solar radiation. The absence of gravity adds complexity by removing the structural anchors on which materials rely as they interact on Earth.

When Gravity Stops

The phenomenon of microgravity fundamentally changes the behavior of materials, introducing complexities in stress distribution, vibration response, and load transport mechanisms. Stainless steel wire ropes, designed with the influence of Earth's gravity, now have to work in environments where their traditional behavior is challenged.

Overcoming Microscopic Threats

The cold welding effect – the unusual fusing of materials in a vacuum – poses an unexpected danger to stainless steel wire ropes. While this phenomenon is fascinating on a scientific level, it can unintentionally weaken critical points along the rope's length, causing unpredictable defects and potential failure.

Testing and Analysis: Critical Measures in Transporting Materials in Space

Rigorous testing and comprehensive analysis are prerequisites to ensure the integrity of stainless steel wire ropes in space operations. Space agencies and manufacturers use a number of techniques to simulate and evaluate performance in zero-gravity environmental conditions, taking into account the limitations of testing in a gravity-dependent facility.

Simulation of Space Stresses

Highly specialized equipment such as vacuum chambers and torsion machines allow researchers to subject stainless steel wire ropes to space-like conditions. By observing the reactions in a controlled vacuum, the behavior of the parts forming the rope can be examined for any deviations from the expected norm.

Case Studies: Space-Ready Ropes

Case studies provide detailed insight into how stainless steel wire ropes are expected to perform in space, revealing their dynamic response during the rigors of satellite deployments and station-keeping maneuvers. By overlaying actual mission data with theoretical models, engineers are constantly improving their understanding and confidence in the material's capabilities.

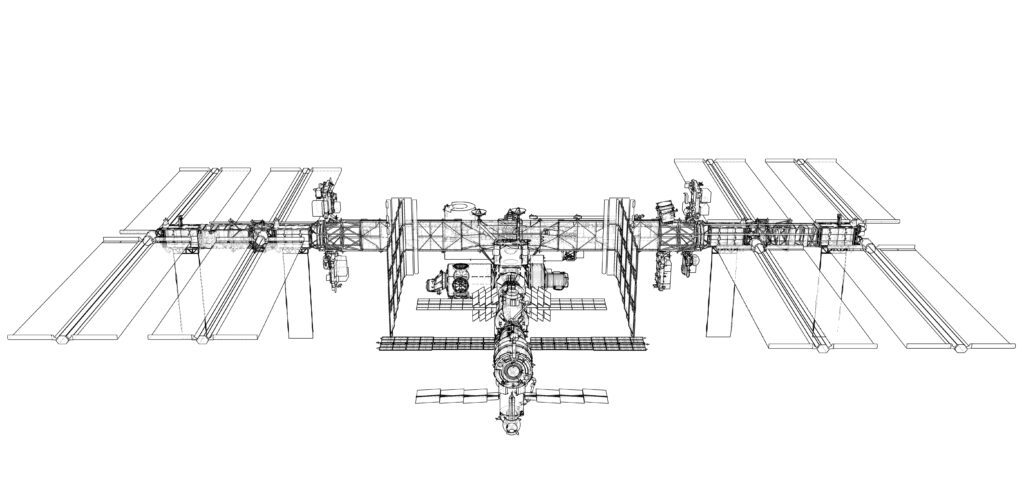

Aerospace Engineering Applications: Weft of the Space Age

From the International Space Station's stabilizing mounts to satellite retrieval and beyond, stainless steel wire ropes are indispensable threads woven throughout the fabric of space technology. Each application represents a challenge encountered and a solution found, underlining the crucial role of the material.

A Supporting Role in The Last Frontier

Satellite docking mechanisms such as boom arms and release latches rely on the precision and flexibility of stainless steel wire ropes. These lifelines are evidence of the harmonious combination of human and material capabilities, enabling payloads to reach their orbital targets.

In the Innovation Orbit

As we move deeper into space, engineers' creativity knows no bounds, encouraging unexpected uses of stainless steel wire ropes. Whether in the construction of space elevators or in attaching spacecraft for orbital dynamics, these materials stand firm as Earth's ambassadors in the cosmos.

Future Developments and Innovations

As the demand for aerospace-grade materials increases, so does the search for innovation in stainless steel wire rope technology. By embracing emerging materials and production techniques, the industry has been on a continuous development trajectory in anticipation of new applications and requirements.

Towards 'Unbreakable' Wire Rope

Artificial intelligence, nanotechnology and advanced alloys are ways being explored to give stainless steel wire ropes even greater flexibility. These 'next generation' ropes are designed not only with the zero-gravity environment in mind, but also with the hazardous environments of celestial bodies in mind, where the line between success and failure is often drawn by the willingness of the materials to cling.

Sustainability in the Stars

As the space industry continues its quest for sustainability, stainless steel wire ropes represent an environmentally friendly material due to their longevity and reusability capacity. Engineers are delving deeper into materials science and trying to close the loop on space debris by designing components for multiple missions.

Conclusion: The Humble Hero in Our Celestial Games

The juxtaposition of stainless steel wire ropes, so ordinary in their terrestrial applications and vital in the extraordinary enterprises of space, is a testament to the far-reaching impact of materials science. As we continue to push the boundaries of our collective knowledge, these humble doyens of resilience will stand front and center, ready to connect us to the promises of the universe.

We Keep Talking

This discovery only scratches the surface of the potential of stainless steel wire ropes. To learn about the latest breakthroughs and discoveries in space materials and engage in dialogue with our community of engineers and enthusiasts, join us as we chart a course through the universe, uncovering the story of stainless steel wire ropes in zero-gravity environments.

Why Choose Samas Wire Ropes?

- Uncompromising Quality: Our steel wire ropes are precision manufactured for unmatched strength and durability.

- Rust Resistance: Our wire ropes, made of high quality steel, provide superior resistance to corrosion and ensure longevity in any environment.

- Versatile ApplicationsSuitable for a wide range of applications from marine rigging to architectural installations, our wire ropes offer reliability and performance.

- Low Maintenance: Our steel wire ropes, which require minimum maintenance, are easy to maintain and save time and effort.

- Expert Service: Our knowledgeable team is dedicated to providing exceptional service by helping you find the perfect wire rope solution for your needs.

- Competitive pricing: Enjoy competitive pricing without sacrificing quality, making our steel wire ropes a cost-effective choice for any project.

- Trusted Reputation: With years of experience, we have gained a reputation for excellence and reliability in delivering the best quality wire ropes.

- Satisfaction Guaranteed: Your satisfaction is our priority. If you are not completely satisfied with your purchase we will work to make it right.

Experience the strength and reliability of Samas Wire Ropes for your next project. For long-lasting superior performance, choose Samas.

Comments are closed