Stainless Steel Profile: Production Process and Areas of Use

Stainless steel profiles are one of the indispensable building blocks of modern industry. They are preferred in many sectors with their features such as corrosion resistance, aesthetic appearance and high durability. So what is a stainless steel profile, how is it produced and in which areas is it used? Here are all the details:

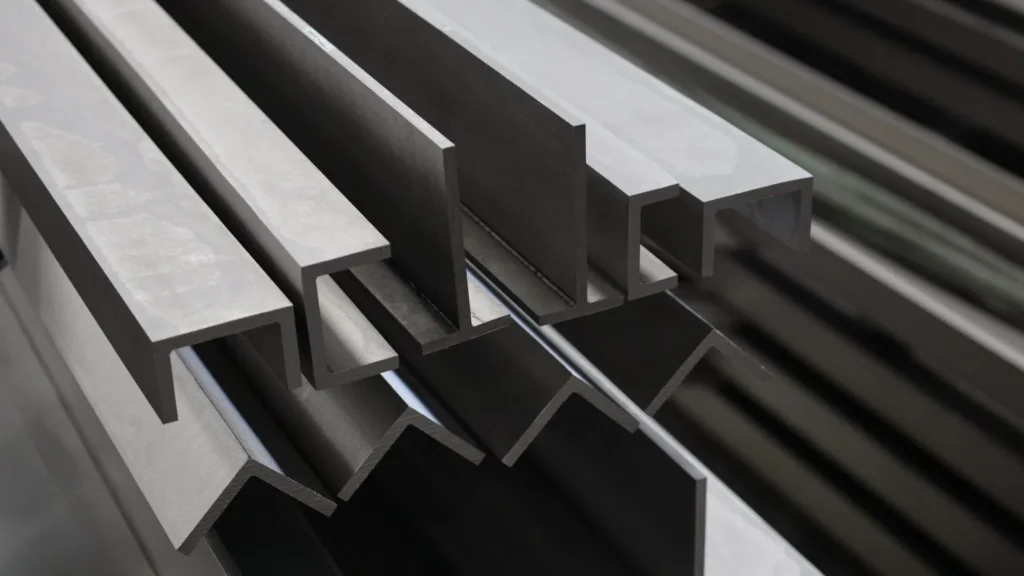

What is a Stainless Steel Profile?

Stainless steel profiles are long metal pieces with a specific cross-sectional shape (square, rectangular, round, angle iron, etc.). These profiles are 304, 316L, Duplex 2205 It is produced in such qualities and designed to suit different industrial needs.

Stainless Steel Profile Production Methods

1. Cold Drawing

- Period:

- Stainless steel rod or tube is forced through a die.

- The cross-sectional shape and dimensions are precisely adjusted through the drawing process.

- Advantages:

- High surface quality and tolerances.

- Production of complex sections (e.g. L or T profiles).

- Area of Use: Precision engineering parts, automotive components.

2. Hot Rolling

- Period:

- The stainless steel billet is heated to 1200-1300°C.

- It is transformed into the desired cross-sectional shape on rolling mills.

- Advantages:

- Production of large size profiles.

- Low cost and fast production.

- Area of Use: Construction, shipbuilding, power plants.

3. Extrusion

- Period:

- Heated steel is forced through a die at high pressure.

- The cross-sectional shape is created according to the mold.

- Advantages:

- Production of complex and hollow profiles.

- Low wastage rate.

- Area of Use: Furniture, architectural applications.

Stainless Steel Profile Types

| Profile Type | Properties | Areas of Use |

|---|---|---|

| Square Profile | Symmetrical structure, high strength | Construction, furniture, machinery manufacturing |

| Rectangular Profile | Large surface area | Decoration, carrier systems |

| Round Profile | Circular section, aesthetic appearance | Railings, architectural details |

| Angle (L Profile) | 90° angle, high strength | Steel structures, racking systems |

| T Profile | T-shaped section | Industrial machinery parts |

Usage Areas of Stainless Steel Profiles

1. Construction and Architecture

- Use:

- Building facades, suspended ceiling systems.

- Stair railings, glass balcony railings.

- Reason for Choice:

- Aesthetic: Glossy or matte surface options.

- Durability: Resistance to weather conditions.

2. Automotive and Transportation

- Use:

- Vehicle chassis and frame systems.

- Support profiles for train and tram rails.

- Reason for Choice:

- Lightness: Provides weight savings.

- Vibration Resistance: Long-lasting performance.

3. Food and Pharmaceutical Industry

- Use:

- Carrier rack systems and conveyor belts.

- Hygienic work benches.

- Reason for Choice:

- Hygiene: Does not hold bacteria, easy to clean.

- 316L quality: Chemical resistance.

4. Energy and Chemical Sector

- Use:

- Pipe support systems and platforms.

- Supporting structures of chemical tanks.

- Reason for Choice:

- Corrosion Resistance: Resistance to acid, base and salt water.

- Duplex 2205: High strength.

5. Furniture and Decoration

- Use:

- Modern furniture designs (tables, chairs, shelves).

- Decorative lighting elements.

- Reason for Choice:

- Aesthetic: Stylish and modern appearance.

- Longevity: Years of use without rust.

Quality Control in Stainless Steel Profile Production

- Chemical Analysis: Cr, Ni, Mo ratios are checked.

- Mechanical Tests: Tensile, compression and bending tests.

- Surface Control: Scratches, cracks and roughnesses are examined.

- Certificates: TSE EN 10088, ASTM A276, ISO 9001.

Stainless Steel Profile Production in Türkiye

- Domestic Production: Erdemir, Izmir Iron and Steel and private steel factories.

- Export: Annual export of 20,000+ tons to Europe, Middle East and Africa.

- Technology: CNC cutting and laser welding investments have increased in the last 10 years.

Frequently Asked Questions (FAQ)

Q: What determines the price of stainless steel profiles?

A: Grade (304, 316L), section shape, size and quantity affect the price.

Q: How should profiles be cleaned?

A: Wipe with pH neutral detergent + soft cloth. Avoid caustic chemicals.

Q: Is it possible to produce profiles with special cross-sections?

A: Yes, we manufacture custom sections according to your CAD drawings.

The Result: A Versatile and Durable Solution

Stainless steel profiles are an indispensable part of modern industry. With the right quality and section selection, you can increase the efficiency of your projects and achieve long-term cost savings.

Why Samas?

✅ Superior Quality and Lifetime Durability

Our products, manufactured with engineering precision, offer a service life beyond industry standards.

✅ Sustainable Production Understanding

We contribute to the ecological balance with our recyclable products and shape the future with a low carbon footprint.

✅ 24/7 Professional Support

Our expert technical team produces instant solutions in all your processes from pre-order to delivery.

✅ Premium Products, Competitive Prices

We make industrial luxury accessible: We offer high-performance steel at flexible pricing that aligns with market dynamics.

✅ Industry Proven Trust

Our expertise, gained over many years, has created a chain of trust crowned with reference projects in more than 62 countries.

✅ Unconditional Satisfaction Commitment

We act on the principle of “the right solution the first time”; if it does not meet your expectations, we take immediate action for revision.

Discover the Samas Difference!

We provide services with our global network in 4 offices in 3 countries, and we try to meet all your needs with technical consultancy for your special projects.

Get a Quote Now ➔

✉️ info@samasinc.com | 🌐 www.samasinc.com

Comments are closed