Steel Ropes in Mining Operations:

Heavy Duty Applications and Challenges

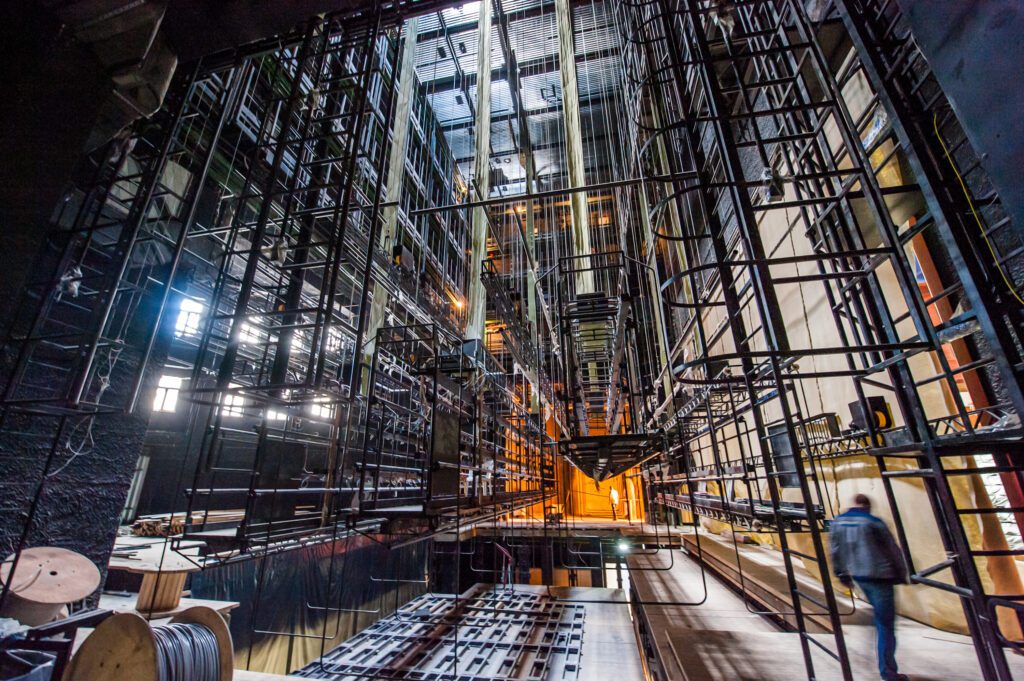

At the heart of mining operations, steel wire ropes stand tall as unsung heroes orchestrating a dance between heavy loads, mining processes and the safety of thousands of people. These resilient giants play such an important role that they are woven into the fabric of the industry – holding together monumental machines not only in the physical sense, but also in maintaining the safety and efficiency standards that mining companies value.

As we explore the deep wells and vast expanses where the world's resources come to the surface, understanding the intricacies of steel wire ropes becomes a necessity for practitioners and engineers. Let's explore the critical role they play, explore the challenges faced, unravel the maintenance mysteries, and applaud the industry's ongoing innovation efforts.

The Unspoken Importance of Steel Ropes in Mining

For those unfamiliar, steel wire ropes may appear to be just metal wires, but the complexity and vital nature of these ropes for the mining industry is second to none. A key component of numerous hoisting and hoisting applications, steel wire ropes transport ores, minerals and resources of countless value that are the lifeblood of a mining operation. Their roles include:

1. Ensuring Safety in Heavy Operations

The reliability and strength of steel wire ropes determine the safety of complex lifting operations. They also manage the peace of mind of these movements, which is essential in operations involving huge excavators or highly dynamic cranes to redirect tons of material.

2. Supporting Heavy Loads in Harsh Environments

No soft terrain or scorching conditions can deter these ropes from their duties. In operations such as mine shaft sinking, where depths can be extreme and loads enormous, the flexibility of steel wire ropes is what stands between a successful operation and disaster.

3. Operational productivity Supporting

In mining, time doesn't just equal money – it often determines the feasibility of the effort. Robust wire ropes contribute to increased productivity by ensuring that machine downtimes are minimized and operational cycles run smoothly.

Navigating the Steel Ropes Minefield: Challenges Encountered

The challenges for steel wire ropes are as relentless as the loads they carry. These include:

1. Corrosion and Wear: Silent Assassins

In mining, ropes are exposed to a cocktail of harmful environmental factors such as corrosive chemicals, moisture and corrosive materials, significantly reducing their lifespan.

2. Fatigue and Stress: Debilitating Forces

Repeated loading and unloading, known as fatigue, wears down the strength of the ropes. Injuries cause stress-related problems that, although not immediately obvious, can lead to catastrophic failure.

3. Environmental Factors: Nature's Fury

Heat, cold, pressure differences and even electromagnetic fields in certain equipment can stress the ropes, accelerating their wear and tear.

Guarding the Guard: Best Practices for Maintaining Wire Ropes

Preventive rope maintenance protocols are essential. Mines can fulfill these by:

Regular Inspections and Maintenance Routines

Adhering to rigorous inspection programs and using advanced inspection techniques such as NDT (Non-Destructive Testing) can detect problems before they escalate.

Proper Storage and Transportation Techniques

Proper storage conditions, including controlling humidity and preventing kinks from forming in stored ropes, can significantly extend the life of ropes.

Safe Use and Monitoring Conditions Training

Equipping staff with the knowledge of correct rope inspection and use, along with modern rope monitoring equipment, including IoT solutions, enables a proactive approach to safety and longevity.

Moving Forward: Innovations in Wire Ropes for Mining

As the industry progresses, the tools of the trade also evolve. Innovations in steel wire ropes include:

Advanced Materials and Coatings

High-performance wires and coatings, including anti-abrasive and anti-corrosion coatings, extend the life and effectiveness of steel wire ropes in harsh mining environments.

IoT Integration for Real-Time Monitoring

IoT solutions now enable real-time analysis of wire rope conditions, alerting operators to potential hazards, and planning maintenance with unprecedented accuracy.

Successful Application Examples

Mining companies around the world have exploited the potential of these innovations, citing significant safety improvements and cost-effective maintenance systems. We examine these success stories by drawing lessons from the pragmatic applications of technological developments.

Call for Constant Dynamism

As mines go deeper and equipment becomes more sophisticated, the demand for flexible and reliable steel wire ropes will increase. The industry is at a turning point that requires a conscious focus on prevention and regular maintenance to ensure both safety and sustainability.

Adopting a forward-looking stance on technology and embracing the ever-evolving landscape of wire rope innovation is not just a strategic decision; It is an ethical responsibility towards the workforce that keeps the mining industry breathing. The path ahead is clear – to conquer the depths or climb the peaks, the mining industry needs a rope as strong as the human spirit that drives it and as durable as the land it seeks to conquer.

As a result, as gray skies loom over the mining industry regarding the future of steel wire ropes, innovation stands as a beacon guiding us through the fog of uncertainty. This article has sought to elucidate the indispensable role of wire ropes in mining, unraveling the web of challenges and charting the course towards best practices and adoption of new technologies. Through this cycle of continuous learning and adaptation, we can elevate not only the equipment, but also the cornerstone of mining: the lives that depend on its safety and efficiency.

For the mining world: Ad undas vires, to great depths, with ropes stronger than steel.

Why Choose Samas Wire Ropes?

- Uncompromising Quality: Our steel wire ropes are precision manufactured for unmatched strength and durability.

- Rust Resistance: Our wire ropes, made of high quality steel, provide superior resistance to corrosion and ensure longevity in any environment.

- Versatile ApplicationsSuitable for a wide range of applications from marine rigging to architectural installations, our wire ropes offer reliability and performance.

- Low Maintenance: Our steel wire ropes, which require minimum maintenance, are easy to maintain and save time and effort.

- Expert Service: Our knowledgeable team is dedicated to providing exceptional service by helping you find the perfect wire rope solution for your needs.

- Competitive pricing: Enjoy competitive pricing without sacrificing quality, making our steel wire ropes a cost-effective choice for any project.

- Trusted Reputation: With years of experience, we have gained a reputation for excellence and reliability in delivering the best quality wire ropes.

- Satisfaction Guaranteed: Your satisfaction is our priority. If you are not completely satisfied with your purchase we will work to make it right.

Experience the strength and reliability of Samas Wire Ropes for your next project. For long-lasting superior performance, choose Samas.

Comments are closed