What is Wire Rope? Understanding the Properties and Structure of Wire Rope!

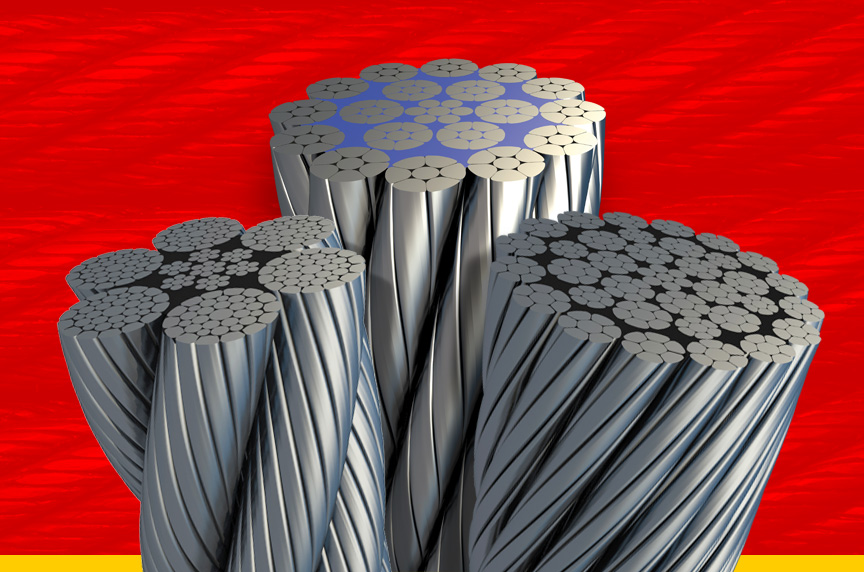

Wire rope is a complex mechanical device that has many moving parts all working in tandem to help support and move an object or load. In the lifting and rigging industries, wire rope is attached to a crane or hoist and fitted with swivels, shackles or hooks to attach to a load and move it in a controlled matter. It can also be used to lift and lower elevators, or as a means of support for suspension bridges or towers.

Wire rope is a preferred lifting device for many reasons. Its unique design consists of multiple steel wires that form individual strands laid in a helical pattern around a core. This structure provides strength, flexibility, and the ability to handle bending stresses. Different configurations of the material, wire, and strand structure will provide different benefits for the specific lifting application, including:

- Strength

- Flexibility

- Abrasion resistance

- Fatigue resistance

- Crushing resistance

- Corrosion resistance

- Rotation resistance

However, selecting the proper wire rope for your lifting application requires some careful thought. Our goal is to help you understand the components of a wire rope, the construction of wire rope, and the different types of wire rope and what they might be used for. This will allow you to select the best performing and longest-lasting wire rope for the job at hand.

A Wire Rope Is a Machine with Many Moving Parts

From childhood, many of us have been conditioned to think of a machine as some device with gears, shafts, belts, cams, and assorted whirring parts. Yet, by the rules of physics, an ordinary pry bar is a simple machine, even though it has only one part.

A wire rope is, in reality, a very complicated machine. A typical 6 x 25 rope has 150 wires in its outer strands, all of which move independently and together in a very complicated pattern around the core as the rope bends. Clearances between wires and strands are balanced when a rope is designed so that proper bearing clearances will exist to permit internal movement and adjustment of wires and strands when the rope has to bend. These clearances will vary as bending occurs, but are of the same range as the clearances found in automobile engine bearings.

Understanding and accepting the “machine idea” gives a rope user a greater respect for rope, and enables them to obtain better performance and longer useful life from rope applications. Anyone who uses a rope can use it more efficiently and effectively when they fully understand the machine concept.

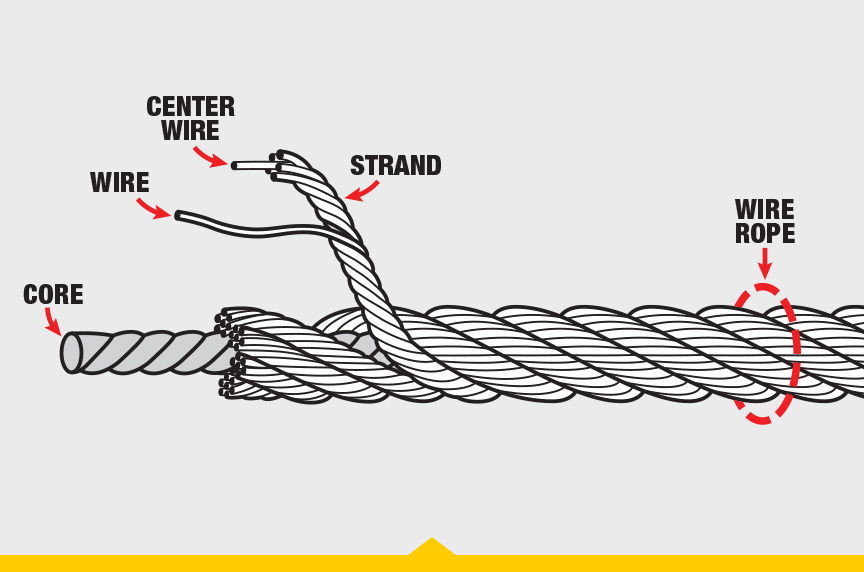

There are four basic components that make up the design of a finished wire rope:

- Wires made from metal that form a singular strand

- Multi-wire strands laid around a core in a helical pattern

- A fiber or steel core

- Lubrication

Wire

Wires are the smallest component of wire rope and they make up the individual strands in the rope. Wires can be made from a variety of metal materials including steel, iron, stainless steel, monel, and bronze. The wires can be manufactured in a variety of grades that relate to the strength, resistance to wear, fatigue resistance, corrosion resistance, and curve of the wire rope.

The wires themselves can be coated but are most commonly available in a “bright” or uncoated finish.

Strands

Strands of wire rope consist of two or more wires arranged and twisted in a specific arrangement. The individual strands are then laid in a helical pattern around the core of the rope.

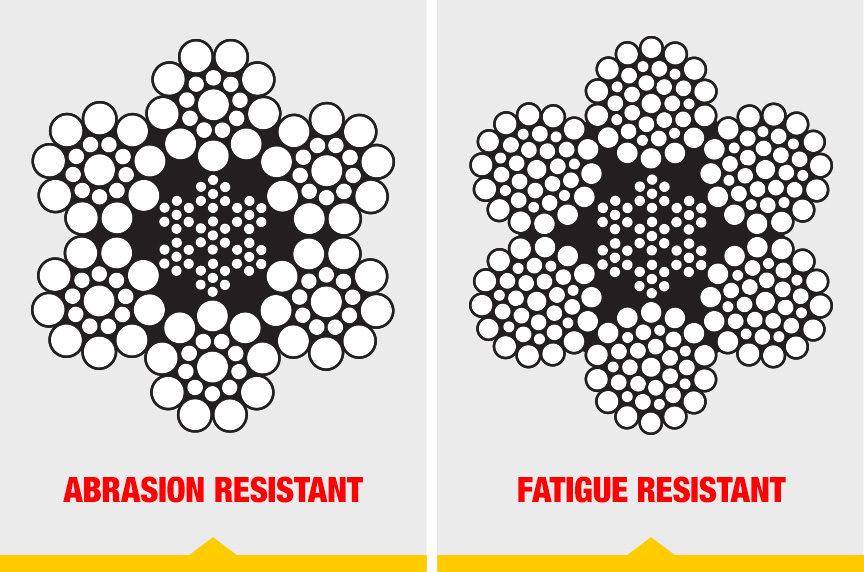

Strands made of larger diameter wires are more resistant to abrasion, while strands made of smaller diameter wires are more flexible.

Core

The core of a wire rope runs through the center of the rope and supports the strands and helps to maintain their relative position under loading and bending stresses. Cores can be made from a number of different materials including natural or synthetic fibers and steel.

Lubrication

Lubrication is applied during the manufacturing process and penetrates all the way to the core. Wire rope lubrication has two primary benefits:

- Reduces friction as the individual wires and strands move over each other

- Provides corrosion protection and lubrication in the core, inside wires, and outside surface

Wire Rope Construction

The following terms help to define the construction and properties of wire rope:

- Length

- Size

- Preformed or Non-Preformed

- Direction and Type of Lay

- Finish of Wires

- Grade of Rope

- Type of Core

Length

The total number of feet (cut to size) when wrapped around the spool and delivered.

Size

This is the specified nominal diameter of the wire rope and can be specified in inches or millimeters.

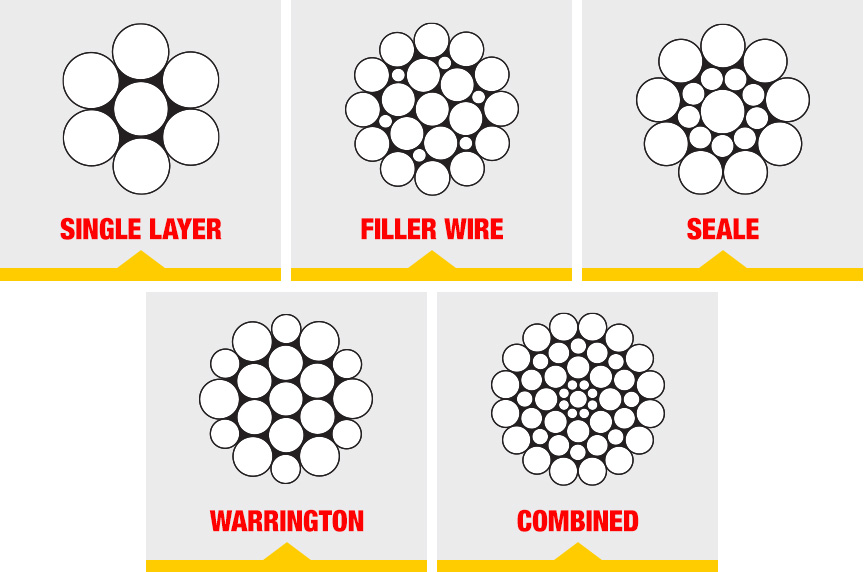

Strand Patterns

The number of layers of wires, the number of wires per layer, and the size of the wires per layer all affect the strand pattern type. Wire rope can be constructed using one of the following patterns, or can be constructed using two or more of the patterns below.

- Single Layer- The most common example is a 7 wire strand with a single-wire center and six wires of the same diameter around it.

- Filler Wire - Two layers of uniform-size wire around a center with the inner layer having half the number of wires as the outer layer. Small filler wires, equal to the number in the inner layer, are laid in valleys of the inner wire.

- Seale Steel Wire Rope - Two layers of wires with the same number of wires in each layer around a center. All wires in each layer are the same diameter. The larger outer wires stop in valleys between the smaller inner wires.

- Warrington Steel Wire Rope - Two layers of wires around a center, with one diameter wire in the inner layer and two diameter wires, large and small, alternating in the outer layer. The larger outer layer wires rest in the valleys and the smaller ones in the crowns of the inner layer.

- Combination - A combination yarn is created using any combination of two or more of the patterns listed above.

Preformed or Non-Preformed

On a preformed wire rope, the strands and wires are formed during the manufacturing process to the helical shape that they will take in a finished wire rope.

Preformed rope can be advantageous in certain applications where it needs to spool more uniformly on a drum, needs greater flexibility, or requires more fatigue-resistance when bending.

Direction and Type of Lay

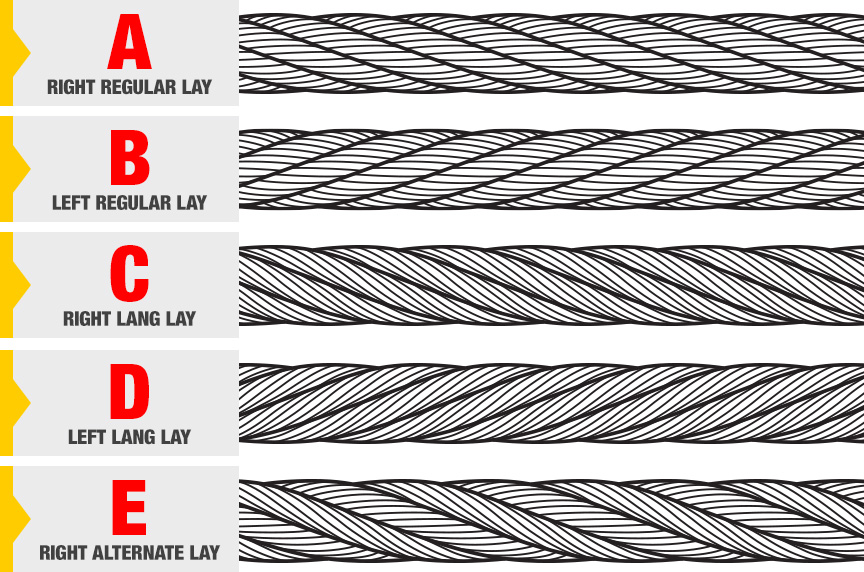

Direction and type of lay refer to the way the wires are laid to form a strand (either right or left) and how the strands are laid around the core (regular lay, lang lay, or alternate lay).

- Regular Lay – The wires line up with the axis of the rope. The direction of the wire lay in the strand is opposite to the direction of the strand lay. Regular lay ropes are more resistant to crushing forces, are more naturally rotation-resistant, and also spool better in a drum than lang lay ropes.

- Lang Lay – The wires form an angle with the axis of the rope. The wire lay and strand lay around the core in the same direction. Lang Lay ropes have a greater fatigue-resistance and are more resistant to abrasion.

- Alternate Lay – The wire rope consists of alternating regular lay and lang lay strands—used mainly for special applications.

Finish of Wires

Zinc coated (galvanized), zinc/aluminum alloy coated (mischmetal), stainless steel, or unfinished steel (“bright”).

Grade of Rope

The strength of wire rope is broken down into different grades, including:

- Improved Plow Steel (IPS)

- Extra Improved Plow Steel (EIPS) is 15% stronger than IPS

- Extra Extra Improved Plow Steel (EEIPS) is 10% stronger than EIPS

The plow steel strength curve forms the basis for calculating the strength of most steel rope wires.

Type of Core

Wire rope cores are designated as:

- Fiber Core (FC)

- Independent Wire Rope Core (IWRC)

- Wire Strand Core (WSC)

A fiber core can be made of natural or synthetic polypropylene fibers. Fiber cores offer greater elasticity than a steel core but are more susceptible to crushing and not recommended for high heat environments.

A steel core can be an independent wire rope or an individual strand. Steel cores are best suited for applications where a fiber core may not provide adequate support, or in an operating environment where temperatures could exceed 180°F.

Based on what we’ve learned above, this wire rope description would provide the user with the following information:

1″ 6 x 25 FW EIP RRL IWRC

- Diameter = 1″

- Number of Strands = 6

- Number of Wires Per Strand = 25

- Strand Pattern = Filler wire

- Grade = Extra Improved Plow Steel

- Direction and Lay = Right Regular Lay

- Core Type = Independent Wire Rope Core

Different Types of Wire Rope

The classifications of wire rope provide the total number of strands, as well as a nominal or exact number of wires in each strand. These are general classifications and may or may not reflect the actual construction of the strands. However, all wire ropes of the same size and wire grade in each classification will have the SAME strength and weight ratings and usually the same pricing.

The table below shows some of the most common wire rope configurations arranged in specific classifications.

| Classification | Outer Strands | Wires / Strand |

|---|---|---|

| 6x7 | 6 | 3–14 |

| 6x19 | 6 | 15–26 |

| 6x36 | 6 | 27–49 |

| 6x61 | 6 | 50–74 |

| 6x91 | 6 | 75–109 |

| 7x19 | 7 | 15–26 |

| 7x36 | 7 | 27–49 |

| 8x7 | 8 | 3–14 |

| 8x19 | 8 | 15–26 |

| 8×36 | 8 | 27–49 |

| 8×61 | 8 | 50–74 |

Besides the general classifications of wire rope, there are other types of wire rope that are special construction and designed for special lifting applications.

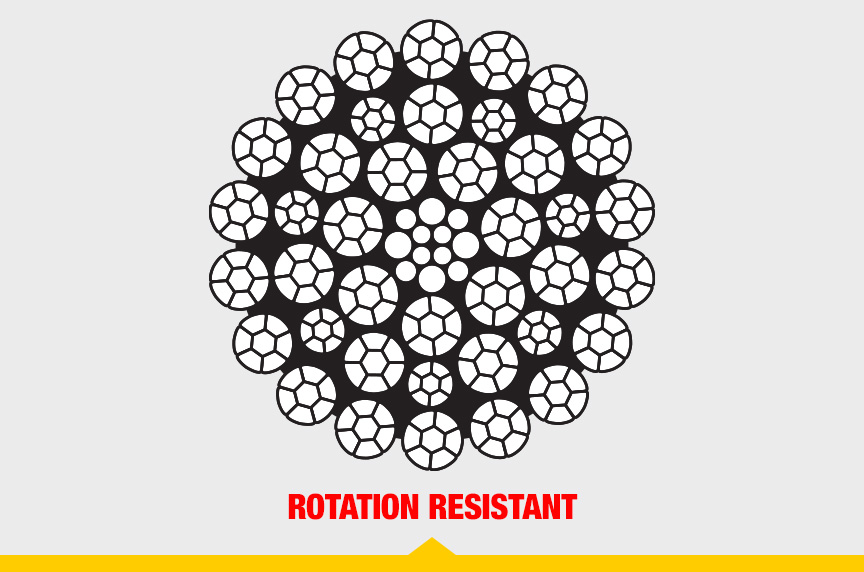

Rotation Resistant Wire Rope

Some types of wire rope, especially lang lay wire rope, are more susceptible to rotation when under load. Rotation resistant wire rope is designed to resist twisting, spinning, or rotating and can be used in a single line or multi-part system.

Special care must be taken when handling, unreeling, and installing rotation resistant wire rope. Improper handling or spooling can introduce twist into the rope which can cause uncontrolled rotation.

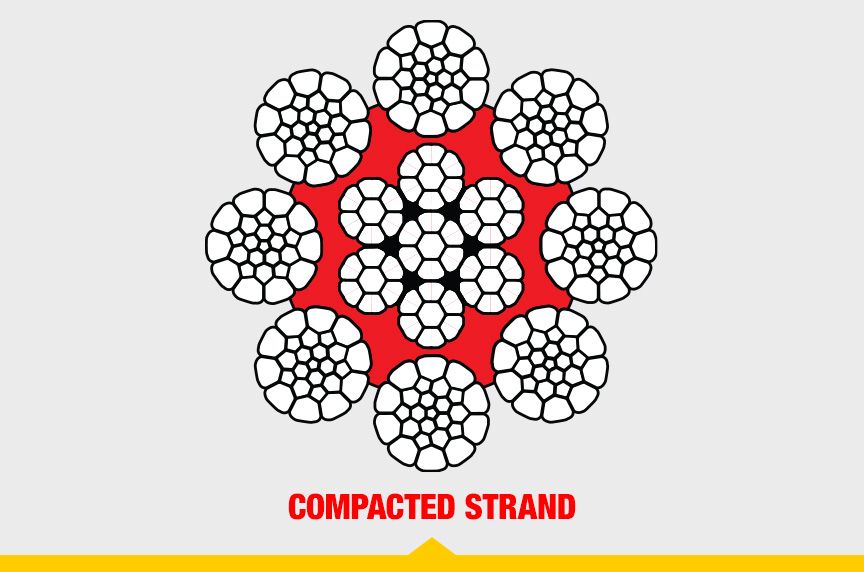

Compacted Strand Wire Rope

Compacted strand wire rope is manufactured using strands that have been compacted, reducing the outer diameter of the entire strand, by means of passing through a die or rollers. This process occurs prior to closing of the rope.

This process flattens the surface of the outer wires in the strand, but also increases the density of the strand. This results in a smoother outer surface and increases the strength compared to comparable round wire rope (comparing same diameter and classification), while also helping to extend the surface life due to increased wear resistance.

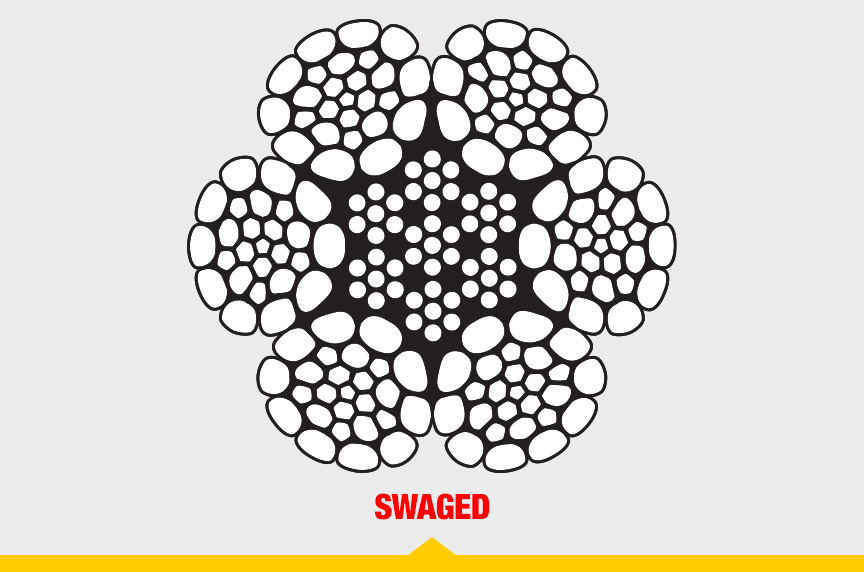

Compacted / Swaged Wire Rope

A swaged wire rope differs from a compacted strand wire rope, in that a swaged wire rope’s diameter is compacted, or reduced, by a rotary swager machine after the wire rope has been closed. A swaged wire rope can be manufactured using round or compacted strands.

The advantages of a swaged wire rope are that they are more resistant to wear, have better crushing resistance, and high strength compared to a round strand wire rope of equal diameter and classification. However, a swaged wire rope may have less bending fatigue resistance.

Plastic Coated Wire Rope

A plastic coating can be applied to the exterior surface of a wire rope to provide protection against abrasion, wear, and other environmental factors that may cause corrosion. However, because you can’t see the individual strands and wires underneath the plastic coating, they can be difficult to inspect.

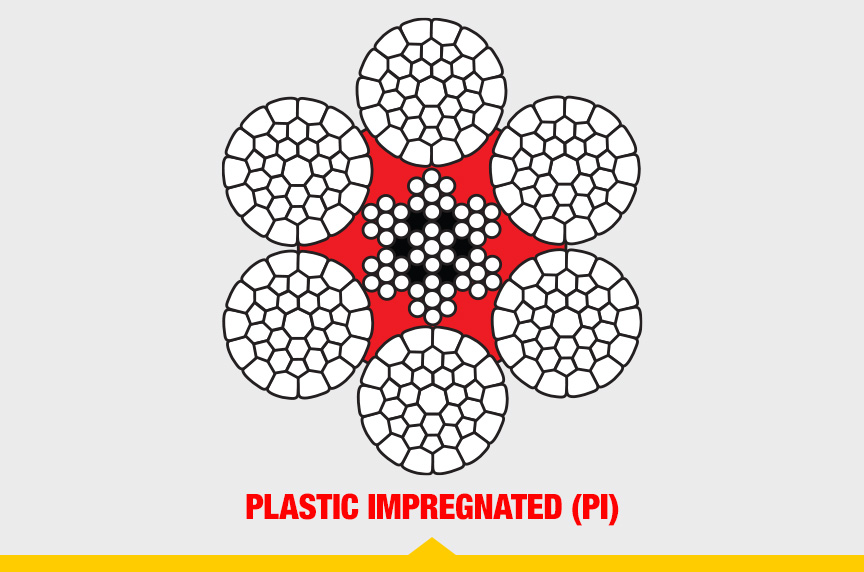

Plastic Impregnated (PI) Wire Rope

Plastic filled wire ropes are impregnated with a matrix of plastic where the internal spaces between the strands and wires are filled. Plastic filling helps to improve bending fatigue by reducing the wear internally and externally. Plastic filled wire ropes are used for demanding lifting applications.

Plastic Coated or Plastic Filled IWRC Wire Rope

This type of wire rope uses an Independent Wire Rope Core (IWRC) that is either filled with plastic or coated in plastic to reduce internal wear and increase bending fatigue life.

Wrapping it Up

Remember, wire rope is a complex piece of mechanical machinery. There are a number of different specifications and properties that can affect the performance and service life of wire rope. Consider the following when specifying the best type of wire rope for your lifting application:

- Strength

- Flexibility

- Abrasion resistance

- Crushing resistance

- Fatigue resistance

- Corrosion resistance

- Rotation resistance

When you select a piece of rope that is resistant to one property, you will most likely have a trade-off that affects another property. For example, a fiber core rope will be more flexible, but may have less crushing resistance. A rope with larger diameter wires will be more abrasion resistant, but will offer less fatigue resistance.

© 2024 Samas Inc. At Samas Inc, we offer all different kinds of wire rope from all of the leading manufacturers. We sell the highest-quality domestic and non-domestic rigging products because product quality and operating safety go hand-in-hand.

If you’re looking for a standard or custom specified wire rope for your lifting project, contact us.

Comments are closed