Innovations in Stainless Steel Alloys for Harsh Space Environments

As we look towards the Moon, Mars and beyond, the lure and challenges of space exploration continue to fuel humanity's quest for the stars. Every visionary breakthrough in this adventure finds a foothold in the unsung heroes of these missions – materials that challenge the harshest environments. Lauded for its flexibility and versatility, stainless steel has remained at the forefront. Today we are exploring the latest technology of stainless steel alloys specifically made to withstand the vacuum, radiation and temperatures of space.

Material Frontier: Stainless Steel in Space Exploration

Space exploration is not only a test of human ingenuity, but also a triumph of materials science. Known for its durability, resistance to corrosion and longevity, stainless steel is a mainstay in the construction of the ships that carry us into space. Unlike materials that struggle under the harsh conditions of space, stainless steel has historically been a reliable choice.

However, the latest developments in space technology have pushed the limits of traditional stainless steel alloys, demanding even higher performance against cosmic brutality. This quest for better alloys is not just an exercise in futurism; It's a necessity in space transportation, where equipment failures can be inexcusable and costly.

Understanding Stainless Steel Alloys: The Key to Leading the Space

Yeniliklere geçmeden önce, paslanmaz çelik alaşımları hakkında temel bir anlayışa sahip olmak gerekir. Paslanmaz çelikler, pasif bir oksit filmi oluşturarak oksijen ve nemin olumsuz etkilerine karşı koyan en az %10,5 krom içeren demir bazlı alaşımlardır. Bu istisnai metal grubu, uzay uygulamaları için aşağıdakiler de dahil olmak üzere bir dizi arzu edilen özelliğe sahiptir:

- High strength/weight ratio: An essential feature for the space race that allows engineers to minimize mass while maintaining structural rigidity.

- Corrosion resistance: It is critical in protecting against the oxidizing conditions of space, where traditional materials would rapidly degrade.

- High and low temperature resistance: An essential asset that can withstand the extreme temperatures encountered during launch, in space, and on reentry.

Current Limitations in Extreme Environments

As impressive as these properties are, traditional stainless steel alloys face critical limitations when faced with extreme conditions. Major challenges include:

- High temperatures: Conventional stainless steels have a melting point, and when a reentry furnace heats a container, some space missions cannot tolerate the temperatures.

- Corrosion: While these alloys are resilient, prolonged exposure to certain corrosive environments in space can lead to degradation over time.

- Radiation effects: High-energy particles in space pose long-term hazards to both equipment and personnel and require materials that reduce their effects.

Latest Innovations in Stainless Steel Alloys

To overcome these limitations, researchers and engineers are pioneering stainless steel alloys tailored to the threats of space. Innovations focus on improving key properties to enable stainless steel to face the challenges of the cosmos head on. Important developments include:

High Temperature Resistant Alloys

New steel blends better resist heat, which is crucial for vital parts like rocket nozzles. They maintain their structural integrity when exposed to searing heat, which can reach 3,315°C (6,000°F) during rocket engine operation.

Corrosion Resistant Compounds

Alloys with advanced passivation properties remain undamaged against the most aggressive space environments, ensuring missions remain productive for long periods of time without succumbing to the dangers of corrosion.

Radiation Shield Features

The need for materials that can shield against cosmic radiation has spurred the development of stainless steel blends that exhibit strong radiation blocking properties, protecting both onboard systems and astronauts.

Applications in Space Technology

Stainless steel applications in space are diverse and expanding. These innovative alloys are found in:

- Rocket Propulsion Systems: The engines that launch spacecraft into orbit and beyond use cutting-edge stainless steel for exceptional heat and corrosion resistance properties that ensure efficient performance even under extreme stress.

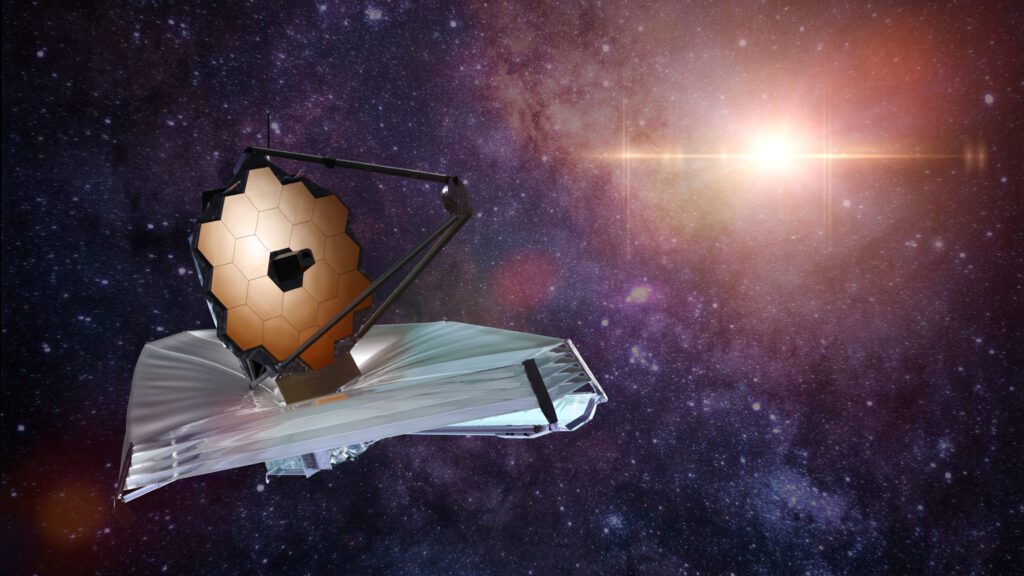

- Satellite Components: The ever-increasing fleet of satellites orbiting Earth are based on stainless steel alloys that provide a stable platform for a wide range of instruments while withstanding the harsh vacuum and thermal cycles of space.

- Spacecraft Structures: Modern stainless steel alloys in the construction of spacecraft such as shuttles and International Space Station components ensure structural integrity throughout the mission life, including the turbulent reentry phase.

Future Trends and Developments

The trajectory of stainless steel alloy developments in the aerospace industry points to a future of even more flexible and specialized materials. Potential trends include:

- Advances in Alloy Composition: Continuous improvement and adaptation of alloy compositions to meet the specific demands of space missions such as lunar bases or terraforming Mars.

- Production Techniques: Innovations in production methods promise to produce stainless steel with superior grain structures, improving mechanical properties and performance against both wear and fatigue.

- Light Stainless Steel: The holy grail of aerospace materials, lightweight stainless steel alloys can bring the benefits of stainless steel to mission profiles that require ultimate weight reduction without sacrificing strength or durability.

Conclusion: Stainless Steel and Space, an Ongoing Saga

The partnership between stainless steel and space has been a partnership of flexibility and courage that has been called “facing the unknown with unwavering certainty.” As we move forward, this relationship will continue to evolve, and stainless steel alloys will form the backbone of our most ambitious missions beyond the Earth's atmosphere. Every innovation, every alloy, and every application represents another step towards the stars, made possible by futuristic metals produced here on Earth.

Why Should You Choose Samas?

- Quality and Durability: Our stainless steel products are precision-crafted for unmatched quality and long-lasting durability.

- Eco-Friendly: Prioritizing sustainability, our stainless steel is fully recyclable and has a low environmental impact.

- Versatile Style: Find modern kitchen appliances, stylish decor and more to beautify any space with timeless stainless steel designs.

- Easy Maintenance: Enjoy trouble-free cleaning and resistance to corrosion with our easy-to-maintain stainless steel products.

- Exceptional Service: Our dedicated team ensures a hassle-free shopping experience with prompt assistance for all your questions.

- Affordable Luxury: Access premium stainless steel products at competitive prices without compromising quality.

- Trusted Reputation: Through years of experience, we have built a reputation for excellence and reliability.

- Satisfaction Guaranteed: Your happiness is our priority. If you are not satisfied, we will fix it.

Experience the excellence of Samas Stainless Steel today.

Comments are closed